A winkelbohrspindel has become an indispensable tool in modern machining and engineering, providing unmatched precision for angle drilling and milling tasks. Its design allows operators to perform complex cuts without repeatedly repositioning the workpiece, significantly improving workflow efficiency. As industries in 2025 demand higher accuracy and productivity, the winkelbohrspindel stands out as a key component in precision engineering setups.

The growing relevance of the winkelbohrspindel is not limited to large industrial plants. Small workshops and CNC facilities also benefit from its versatility, enabling them to handle intricate machining operations with minimal setup. By maintaining consistent angles and reducing errors, the winkelbohrspindel ensures higher quality output while saving time and resources, making it a preferred choice across multiple sectors.

What Is a Winkelbohrspindel?

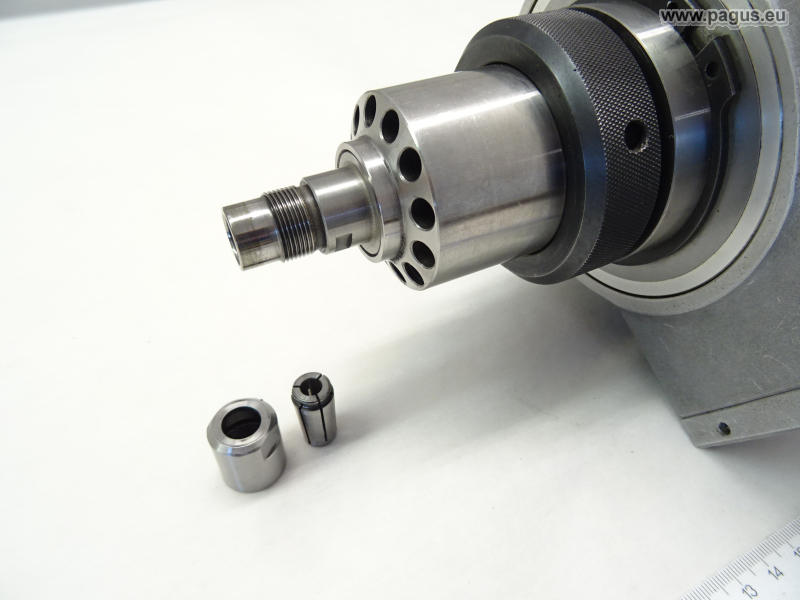

A winkelbohrspindel is essentially an angle drilling spindle that redirects the rotation of a cutting tool, allowing precise drilling or milling at specific angles. This feature is critical for components requiring tight tolerances or complex geometrical designs. Unlike traditional spindles, the winkelbohrspindel eliminates the need for multiple setups, streamlining manufacturing processes while maintaining accuracy across all operations.

The unique internal gearing and bearing systems of a winkelbohrspindel enable smooth power transfer, reducing vibration and tool wobble. This ensures that even high-speed drilling maintains precise alignment. Engineers and machinists rely on the spindle for its stability and performance, making it a staple tool in industries ranging from automotive to aerospace, where precision is a non-negotiable requirement.

Evolution of the Winkelbohrspindel

The evolution of the winkelbohrspindel reflects significant technological advancements in machining. Early designs served primarily for simple manual drilling, providing basic angle adjustments. Over time, the spindle has transformed into a high-performance tool compatible with CNC and multi-axis machinery, meeting the increasing demands for precision, speed, and automation in modern production environments.

In 2025, the latest winkelbohrspindel models feature improved heat-resistant materials, enhanced alignment systems, and advanced bearings to ensure long-term reliability. These innovations allow the spindle to operate efficiently under heavy workloads while maintaining exact drilling angles. As manufacturing shifts toward automated and smart systems, the winkelbohrspindel remains an essential tool for maintaining high-quality standards in production.

Types of Winkelbohrspindeln

Winkelbohrspindeln are available in several types, each tailored to specific machining requirements. Standard spindles are ideal for general-purpose drilling, offering a balance of torque and speed suitable for everyday operations in workshops. They provide consistent performance without the need for high-end industrial setups, making them accessible for a wide range of users.

High-speed winkelbohrspindeln are designed for delicate operations, such as micro-drilling and lightweight materials, delivering smooth finishes with minimal vibration. Heavy-duty spindeln, on the other hand, are engineered for large-scale industrial applications where high torque and durability are essential. Each type serves a distinct purpose, allowing engineers to select the most appropriate spindle based on project demands, material hardness, and machine compatibility.

Key Benefits of Using a Winkelbohrspindel

One of the primary benefits of a winkelbohrspindel is its ability to enhance machining precision. By maintaining exact angles, it reduces errors and rework, ensuring components meet strict tolerance requirements. This is particularly crucial in sectors like aerospace, automotive, and precision engineering, where even minor inaccuracies can lead to costly failures.

Another significant advantage is increased productivity. The winkelbohrspindel allows operators to perform angle drilling without multiple setups, saving valuable time and reducing labour costs. Its versatility across different machine types and materials further increases operational efficiency. The spindle’s consistent performance also contributes to improved product quality, making it a cost-effective and reliable investment for manufacturers.

Applications of Winkelbohrspindeln

Winkelbohrspindeln are widely used in CNC machining centres, where precision and versatility are essential. They enable multi-axis operations, allowing engineers to drill, mill, and shape components without repositioning the workpiece repeatedly. This capability significantly reduces production time while maintaining high accuracy.

In automated production lines, winkelbohrspindeln ensure consistent and reliable performance, supporting robotic arms and high-speed CNC machines. Small workshops and custom manufacturing facilities also benefit from their flexibility, using them for prototype development, repairs, and specialised assembly tasks. Overall, the spindle’s adaptability makes it suitable for a wide range of industrial and mechanical applications.

How to Choose the Right Winkelbohrspindel

Choosing the correct winkelbohrspindel depends on several factors, including the material being drilled, the required torque, and the desired speed. Hard metals like steel necessitate durable, high-torque spindles, while softer materials such as aluminium or composites can be machined with lighter, high-speed variants. Evaluating these specifications ensures optimal performance for specific tasks.

CNC compatibility and angle flexibility are also important considerations. The spindle must fit securely into the machine’s toolholder and allow for the necessary angular adjustments. Long-term durability and maintenance requirements should guide purchasing decisions, as investing in a premium model often results in lower repair costs, improved accuracy, and extended operational life.

Installation and Maintenance Tips

Proper installation of a winkelbohrspindel is essential for optimal performance. Ensure the spindle is securely mounted and aligned correctly with the machine’s axis. Misalignment can cause vibration, reduce cutting accuracy, and damage both the tool and workpiece. Following manufacturer guidelines during setup ensures consistent results.

Regular maintenance is equally critical. Lubricate bearings, inspect gears for wear, and clean the spindle to prevent debris accumulation. Monitoring for signs of unusual vibration or noise can prevent larger issues. With proper care, a high-quality winkelbohrspindel can last for many years while maintaining precision and efficiency.

Conclusion

The winkelbohrspindel has proven itself as a cornerstone of modern precision engineering. Its ability to maintain exact drilling angles, improve productivity, and support a variety of industrial applications makes it an indispensable tool in 2025. Investing in the right spindle ensures higher-quality output, reduced production time, and long-term reliability.

FAQs

What is a winkelbohrspindel used for?

A winkelbohrspindel is used for angle drilling and milling tasks requiring precise directional control during machining operations.

Can a winkelbohrspindel be installed on any CNC machine?

Most CNC machines support the spindle, but compatibility depends on toolholder type and machine specifications.

How often should a winkelbohrspindel be maintained?

Regular maintenance, including lubrication, inspection, and cleaning, is recommended based on usage frequency.

Is a high-end winkelbohrspindel worth the investment?

Yes, premium models offer better precision, durability, and long-term performance, reducing maintenance costs.

How long does a winkelbohrspindel typically last?

With proper care, a high-quality spindle can last several years while maintaining accurate and reliable performance.